Environmentally Conscious and Economically Sound Machine Dismantling Forum > Gurnee

> Electrical Machinery

> Rectifiers

> Armorcoat, garage epoxy floor coating kit ,

Armorcoat, garage epoxy floor coating kit ,

Industrial Grade Garage Flooring Coating Kit. We Just Went Residential.

Armorcoat Is Rated One Of the Top Manufacturers of Floor Coatings By World Of Concrete.

Armorcoat Offers 70 Different Types Of Floor Concrete Coating Systems.

Armorcoat is an affordable and durable solids epoxy coating designed to enhance the look and longevity of concrete garage and workshop floors compare to water base epoxy. Come with lifetime warranty compare to other company who offer little or no warranty.

Armorcoat flooring is weather-resistant, and unharmed by rain, snow, oil, and flooding. This resistance is due to the fact that epoxy coatings, unlike paints, come in two parts. When mixed, a catalyzing process changes these two parts from a liquid to a permanent solid. In contrast, paints are carried in water or solvent bases that evaporate to leave the finish. If you reintroduce one of those carriers to the surface, the paint often is able to re-dissolve back into a liquid state.

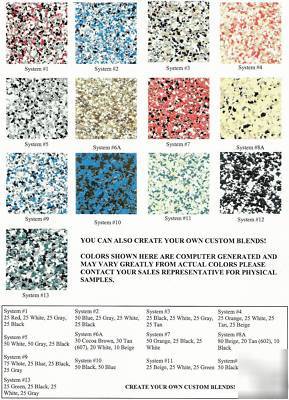

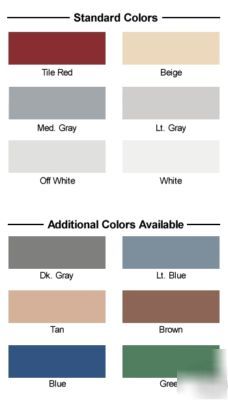

Armorcoat epoxy coating are available in 12 standard colors{ Chart Below } with a variety of add-ons. A detailed product list is below. A standard kit coats approximately 550 square feet of concrete floor, and custom coloring is available. We also can customize your kit to fit any Square footage needed with additional contractor pricing. Color chips are available in any combination and cost is additional $ 9.00 a pound.

Two Gallons of our 1144 High Performance Epoxy Primer

Two component solvent based epoxy coating that exhibits excellent characteristics for abrasion

resistance, chemical resistance & substrate penetration. This products is suitable as a primer for

High build coatings or vinyl chips

One & Half Gallons of our 3200 High Performance Urethane

Two component (semi-gloss) aliphatic polyurethane floor sealer that exhibits excellent

Characteristics for abrasion resistance , chemical resistance, flexibility , weathering

We Can Customize Your Kit To Meet Any Square Footage

Chips: (also known as color "flakes" or "fleck") are integrally colored, random sized particles. Chips are commonly used as a decorative component in resin-based flooring systems designed to enhance residential, commercial, and industrial environments such as garages, utility rooms, basements, high traffic foyers, entryways, corridors, restrooms, and warehouse spaces. After more than 15 years of production, there are no known Chip incompatibilities with resin systems.

NON-SKID Additive: Are small granular particles that are to be incorporated into the epoxy coatings during the mixing process to make your surfaces less slippery. Is fine enough to be easily encapsulated by the resin system. Consists of Aluminum Oxide not Sand in which it does not inhibit the durability of our coatings.

Aluminum Oxide High-Ware: A fine power when added into the coating it increases the Tabor Abrasion 28% in which constitute your floor to be more durable for heavier traffic.

Self Leveling Easy Application Slip Resistant

Industrial Grade Thicker Than a Water Based Resists Hot Tire Marks

Oil Resistance Salt Resistance Chemical Resistance

Abrasive Resistance Dust Proofing Surface Restoration

We have many successful projects behind us. We list our bigger and more diverse references. GM, Ford, Chrysler, Lexus, Toyota, KIA, Budweiser, Frito-Lay, Wal-Mart, Sam's, Bed Bath Beyond, Tractor Supply, Brinks, Dick's Sporting Goods, Target, Coca-Cola, Lincoln-Electric

Professional Installation Available in the following Cities. Cleveland, Ohio, Dallas Fort Worth, Texas, Fort Myers, Florida, Las Vegas, Nevada & Denver, Colorado

_____________________________________________________________________________________________________________________________

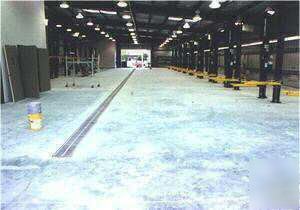

We have tried various manufacturers concrete coatings in our previous facilities and were very disappointed with the durability of the coatings we have chosen. During the construction of our new 42,000 sq. ft industrial warehouse, we did not even want to install any type of coating, but our Building Contractor recommended ArmorCoat products.

We decided to install Armorcoat high performance urethane. We had very high traffic with steel wheels, 6-7 days per week, 2 shifts per day. Armorcoat urethane still looks like new after 4 years - unbelievable! I would recommend your products to anyone looking for a great, durable coating. I was also impressed with your staffs courtesy and professionalism.

We could not be happier with the results! Our shop/warehouse looks GREAT. Have a Good Year!

_____________________________________________________________________________________________________________

PREPARING A CONCRETE FLOOR BY ACID ETCHING

Sweep the floor clean and dispose of dust. Remove from the floor any contaminant, including oil and grease. Dampen the floor and apply a 5 to 1 solution of muriatic acid and water The acid should bubble vigorously when applied to the concrete. Coverage should be about 1 gallon of solution per 100 square feet. Allow reaction between solution and concrete to occur for approximately 3-5 minutes, then follow with a stiff broom to remove surface laitance. (be careful not let the acid dry before you rinse) Rinse the etched surface with a hose, or preferably with a high pressure washer.

If use of a pressure washer is not possible, rinse and remove water a minimum of three times to ensure a complete rinse is obtained. Do not let the acid dry out on the floor. Continue broom scrub while rinsing with clean potable water.

Household ammonia may be added in the rinse to help neutralize the acid. Pick up the water with a wet & dry vac. Allow the surface to completely dry then vacuum again to remove fine particles loosened by the acid-etch.

Garage floor coverings can be installed over most concrete garage floors, providing they are properly prepared.

A good garage floor system will consist of a primer, and a top coat. A primer coat is necessary to ensure a good bond. Apply the primer with a 9" or 18" shed resistance roller and a 3 or 4 inch cut brush to cut in your corners and allow to dry. When the surface is dry to the touch, apply the epoxy or urethane top coat. If using color chips broadcast the chips evenly into the wet base. The chips can be applied lightly to the wet primer base color or heavily for increased coverage and durability. Blow or sweep off loose flakes. Next seal the system with a finish coat. Armorcoat recommends our two-part aliphatic, urethane top coat. They re the Cadillac of systems They are UV resistant, so they won t yellow or fade in the sunlight like epoxies do. That what make are system long lasting. Allow floor to dry for 48 hours before allowing foot traffic and up to five days for vehicle traffic. Two sealer coats may be required if a heavy full broadcast is applied.

* Recommended Dry Film Thickness: 13 Mils

* Packaging: 3 gallon top coat kit and 2 gallon primer kit

* Mixing Ratio: Top Coat 2:1 by volume

* Mixing Ratio: Primer 1:1 by volume

* Application Temperature: 50 F to 100

If you re a Contractor interested in are product line Armorcoat can help you meet your need . We specialize in 70 different types of coatings. Please feel free to contact us for further information.