Environmentally Conscious and Economically Sound Machine Dismantling Forum > Gurnee

> Modern Stuff

> Light Emitting Sources

> 2010 cnc plasma cutting system 6FT by 12FT, HSD130

2010 cnc plasma cutting system 6FT by 12FT, HSD130

OMICRON PC-10612 Chassis and integration

Heavy Unitized Tank Construction

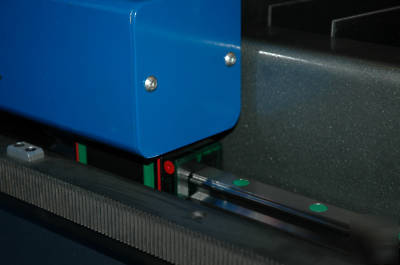

Gantry Is Heavy Wall Steel Tubing W/Double Linear Ways Set In Machined Register

Articulating Mount Hypertherm Automation EDGE Ti (3) Axis CNC Control

Precision Planetary Gear Heads (with <5 arc min. backlash)

750 IPM Rapid Traverse Speed

300 IPM Contour Cutting Speed

Precision Ground Linear Ways 2 on X and 1 on Y Drive Axis

(same type used in vertical mills)

Fully Enclosed Heavy Duty Cat Track Cable Carriers on Both X & Y Axis

Matched Heavy Duty Presision Ground Gear Rack

Effective Cutting Size: 72" x 144"

Table Load Capacity: 4500 lbs

Positioning Accuracy: +/- 0.001"

Hypertherm HSD130 HySpeed LongLife Oxygen plasma power supply: Brochure

Click here to download HSD130 brochure. http:// /hsd_130/HSD130_Brochure.pdf

Mild Steel Dross free 16 mm (5/8")

Production (pierce) 25 mm (1")

Severence (edge starts) 38 mm (1-1 2")

Production (pierce) 20 mm (3/4")

Severence (edge starts)25 mm (1")

Production (pierce)20 mm (3/4")

Severence (edge starts) 25 mm (1")

(Mild steel) Optimum quality 12 mm (1/2") 2200mm/m(80ipm)

(Plasma/shield) Mild steel 02/Air, Air/Air

Stainless steel Air/Air, N2/N2,

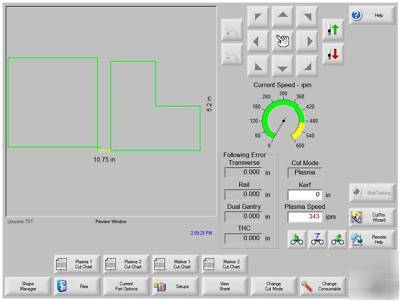

Hypertherm EDGE Ti CNC Control

Display 15" glass touchscreen (surface acoustic wave technology) Memory 1GB USB interface

Dimensions 435 mm (17.125") W; 463 mm (18.22") H; 316 mm (12.43") D

Temperature range -10 C to 40 C ambient (14 F to 104 F ambient)

Warranty Two-year warranty standard

Operator s console Two-station Opcon standard

Operating voltage and frequency 100 240V, 50/60 Hz

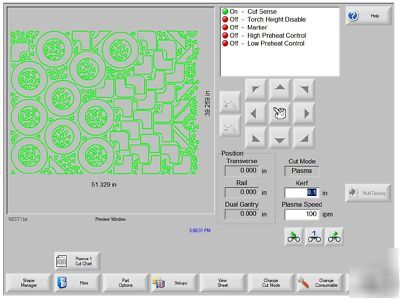

Software utilities Part Program Support (PPS), Remote Help, networking, Autogas support, DXF import, and simple shape nesting

Using the CutPro Wizard new operators can be ready to cut production parts in less than 5 minutes. Built-in two-station operator s console, with tactile joystick, speedpot, and torch position control for easy operation. Network and USB access for part program loading and software updates. Built-in help and cutting optimization tips for improving table performance and process outcomes on demand.

Durable glass touchscreen utilizing surface acoustic wave technology. Air cooling to reduce stress on electronic components without dust ingress. Designed and stress tested to ensure consistent operation in the harsh plasma cutting environment. Intuitive hardware service kit helps rapidly isolate system errors. Hinged doors and removable panel for convenient component access. 2-year warranty standard.

Hypertherm s proprietary Phoenix software is the core operational interface and is common across the entire Hypertherm family of CNC systems. The software is designed specifically for the X-Y and bevel cutting market.

Key benefits include: Integrated communications to plasma and torch height control systems for automated and expert control of the cutting process. Built-in cut charts for automatically setting process parameters for mild steel, stainless, and aluminum to enable consistently optimized cutting performance. Wizards and diagnostic support tools that enable easy setup, use and rapid troubleshooting.

Controlled inturnally with the EDGE Ti controller for seamless Hypertherm integration.

6" (152 mm) range of motion at up to 200 ipm (5080mm/min)

Timed initial height sensing (IHS)

Arc-voltage sensing with 50 V - 210 V range of settings at 1 V

Simple operational controls and fault indicators

Built-in magnetic torch mount breakaway protects the torch from plate collisions

**Notice: This chassis is in stock at our Las Vegas facility, the integration of this system will require 1 to 3 weeks from date of 50% deposit. Balance will be due prior to deposit.

Installation and training are included anywhere in the US.

Some options picture may vary.

Axis builds machines of all specifications: .