Environmentally Conscious and Economically Sound Machine Dismantling Forum > Gurnee

> Tips and Advices

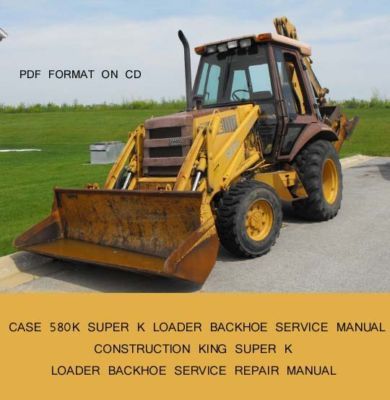

> Case 580 super k loader backhoe service manual 580K ck

Case 580 super k loader backhoe service manual 580K ck

CASE 580 SUPER K LOADER BACKHOE SERVICE REPAIR MANUAL

CASE 580 580SK (CONSTRUCTION KING) SUPER K

LOADER BACKHOE SERVICE REPAIR MANUAL

This is PDF Manuals on CD Which Contain 1285 Pages

which Loaded with the detailed information schematics & diagrams

Don t Pay Repair fee Save Money Do Your Own Repair Now

Alert this is Not For Resell I have Notes All Over This Manual

For More Detail Please See The Following Information and better understanding

1001 STANDARD TORQUE SPECIFICATIONS

Torque Specifications - Decimal

Torque Specifications - Steel Hydraulic Hardware

Torque Specifications - Metric Hardware

Torque Specifications - O-ring Face

Section 1002 FLUIDS AND LUBRICANTS

1002-2 CAPACITIES AND LUBRICANTS

Engine Oil Capacity with Filter Change Type of oil

Capacity with auxiliary tank Type of fuel

Hydraulic System Hydraulic reservoir refill capacity Type of oil

ENGINE SPECIFICATION DETAILS Cylinder Block

Valve Seat Installation Dimensions

ENGINE REMOVAL AND INSTALLATION

REMOVING AND INSTALLING THE TORQUE CONVERTER

INSTALLING THE FRONT ENGINE SUPPORT

SPECIFICATION DETAILS 4-390 Diesel Engine

CYLINDER HEAD AND VALVE TRAIN 4-390 Diesel Engine

CHECKING AND RESURFACING THE CYLINDER HEAD

VALVE GUIDE REPLACEMENT 14 mm Replacement Valve Guides

11 mm Replacement Valve Guides

INSPECTION OF THE VALVES AND VALVE SEATS

REFACING INTAKE AND EXHAUST VALVES AND VALVE SEATS

ADJUSTING THE ROCKER ARM TO VALVE CLEARANCE35-39

Crankshaft, Pistons, Rods, Sleeves, Camshaft, Bearings, Seals and Flywheel

FONT OIL SEAL AND WEAR SLEEVE INSTALLATION

REAR OIL SEAL AND WEAR SLEEVE INSTALLATION

RECONDITIONING THE ENGINE CYLINDER BLOCK

Checking and Resurfacing the Cylinder Block

Reconditioning the Cylinder Block for Oversize Pistons

Reconditioning the Cylinder Block for Sleeves

PISTON AND CONNECTING ROD DISASSEMBLY AND INSPECTION

PISTON AND CONNECTING ROD ASSEMBLY AND INSTALLATION

REPLACEMENT OF THE MAIN BEARINGS WITHOUT REMOVING THE CRANKSHAFT

CRANKSHAFT RECONDITIONING Grinding a Crankshaft

Oil Pan, Oil Pump, Oil Cooler and Oil Filter Housing

OIL FILTER HOUSING AND OIL COOLER

Thermostat, Water Pump, Fan Pulley and Belt Tensioner

SERVICING THE TURBOCHARGER Removal

Turbine Wheel Horizontal Movement

CAUSES OF PREMATURE TURBOCHARGER FAILURE

FUEL INJECTORS 4-390 Diesel Engine

Locating Faulty Injectors at the Fuel Pump

Locating Faulty Injectors at the Cylinder Head

INJECTOR SLEEVE (9 mm BORE TO 7 mm BORE) Installation

Pump Drive Gear, Fuel ShutOff Primer Pump and Pump Timing

REMOVAL AND INSTALLATION OF ELECTRICAL COMPONENTS

Gauge, Voltmeter, or Tachometer Removal and Installation8

ELECTRICAL SPECIFICATIONS, TROUBLESHOOTING,

Starting, Charging, and Instrument Cluster Circuits

Warning Buzzer, Parking Brake, Backup Alarm, and Clutch Cutout

Return-To-Dig, Cab Relay, Lamp Switches, Turn Signal and Flashers

Flood Lamp Switch, High Pressure Switch, and Air Conditioning Compressor Clutch

USING BOOSTER BATTERIES TO START THE ENGINE

ALPHABETICAL INDEX OF COMPONENTS

SPECIFICATIONSSee Section 4001

BOOSTER BATTERIESSee Section 4001

Inspecting and Cleaning the Battery

PREPARING A DRY CHARGED BATTERY FOR USE9

INSPECTION AND TESTING OF ROTOR

INSPECTION AND TESTING OF STATOR

INSPECTION AND REPLACEMENT OF BEARINGS

Gauge or Tachometer Removal and Installation4

Hydraulic Filter and Air Filter5

Water Temperature, Oil Temperature, or Fuel Level6

SPECIFICATIONS, SCHEMATIC AND TROUBLESHOOTING

CHECKING THE PRESSURE SETTING OF THE RELIEF VALVE

ADJUSTING THE PRESSURE SETTING OF THE RELIEF VALVE

CHECKING PISTON PACKING FOR THE STEERING CYLINDER

TWO WHEEL DRIVE STEERING CYLINDER4

FOUR WHEEL DRIVE STEERING CYLINDER

FRONT AXLE, TWO WHEEL DRIVE MACHINES

KiNGPIN BEARINGS AND THRUST BEARINGS

REMOVAL AND DISASSEMBLY OF SWIVEL HOUSING

ASSEMBLY AND INSTALLATION OF SWIVEL HOUSING

REMOVAL OF DIFFERENTIAL CARRIER

DISASSEMBLY OF DIFFERENTIAL CARRIER

INSPECTION OF DIFFERENTIAL PARTS

ASSEMBLY OF DIFFERENTIAL CARRIER

INSTALLATION OF DIFFERENTIAL CARRIER

Removal and Installation o* Power Train Components6001

Transmission Specifications and Schematic6002

Rear Axles and Planetaries6201

Differential and Differential Lock6203

Torque Converter Charging Pump, Output Shaft, And Converter Housing6205

REMOVAL AND INSTALLATION OF POWER TRAIN COMPONENTS

REMOVING THE TORQUE CONVERTER HOUSING AND TORQUE CONVERTER

INSTALLING THE TORQUE CONVERTER AND TORQUE CONVERTER HOUSING

SCHEMATIC OF TRANSMISSION HYDRAULIC SYSTEM

Problem: Machine Will Not Move

Problem: Oil in Transmission Too Hot

Problem: Clutch Discs Wear Too Fast or Are Burned

Problem: Brake Discs Wear Too Fast

CHECKING OUTPUT OF CHARGING PUMP AND SETTING OF CHARGE PRESSURE RELIEF VALVE

CHECKING CONVERTER IN PRESSURE AND FLOW

CHECKING CONVERTER OUT PRESSURE AND FLOW

CHECKING LUBRICATION FLOW AND PRESSURE FOR CLUTCHES

CHECKING LUBRICATION FLOW FOR PINION SHAFT

Cross Sectional Drawing of the PTO Clutch

Cross Sectional Drawing of the PTO Valve

SERVICING THE REAR AXLES AND PLANETARIES

DIFFERENTIAL AND DIFFERENTIAL LOCK

SERVICING THE DIFFERENTIAL AND DIFFERENTIAL LOCK

TORQUE CONVERTER CHARGING PUMP, OUTPUT SHAFT,

SERVICING THE TORQUE CONVERTER HOUSING

SERVICING THE INTERMEDIATE SHAFT

Checking Ring Gear and Pinion Tooth Contact

REMOVAL AND INSTALLATION OF THE MAGNETIC SPEED SENSOR

INSTALLATION OF TRANSAXLE REAR COVER45

REMOVAL AND INSTALLATION OF BRAKE COMPONENTS

REMOVING AIR FROM THE BRAKE SYSTEM

PARKING BRAKE See Section 7000

REMOVING AIR FROM THE BRAKE SYSTEMSee Section 7002

Removal and InstallationSee Section 7002

REMOVAL AND INSTALLATION OF HYDRAULIC COMPONENTS

SWING SEQUENCE VALVE ADJUSTMENT

THREE-POINT HITCH CONTROL VALVE

HYDRAULIC SCHEMATICS, SPECIFICATIONS AND TROUBLESHOOTING

TROUBLESHOOTING PROCEDURE FOR PROBLEM IN ALL CIRCUITS

TROUBLESHOOTING PROCEDURE FOR PROBLEM IN A SINGLE CIRCUIT

CHECKING OUTPUT OF PUMP WITH FLOWMETER

CIRCUIT RELIEF VALVES FOR LOADER AND BACKHOE CONTROL VALVES

CIRCUIT RELIEF VALVE FOR THE THREE POINT HITCH CONTROL VALVE

ADJUSTING THE MAIN RELIEF VALVE OR A CIRCUIT RELIEF VALVE

Three Point Hitch Control Valve

LOADER THREE POINT HITCH SCHEMATIC

SEPARATING THE VALVE SECTIONS5

ASSEMBLING THE VALVE SECTIONS6

Loader Bucket and Lift Backhoe Extension Bucket Swing, Clam Stabilizer and Dipper Cylinders

Lift Cylinder for the Three-Point Hitch

Tilt Cylinder for the Three-Point Hitch

Pitch Cylinder for the Three-Point Hitch

EXPLODED VIEW OF BACKHOE CONTROL VALVE

BUCKET, DIPPER, AND EXTENDABLE DIPPER SECTIONS

EXPLODED VIEW OF SWING SEQUENCE VALVE

CROSS SECTION VIEW OF SWING SEQUENCE VALVE

Specifications 8009-2 Exploded View

Separating the Valve Sections 8009-3 Inlet/Outlet and Auxiliary Section

Assembling the Valve Sections 8009-5 Disassembly

Lift Section 8009-6 Exploded View

Exploded View 8009-10 Inspection

Assembly 8009-11 Relief Valves

Tilt and Pitch Sections 8009-15 Disassembly

Disassembly 8009-15 Inspection

POSSIBLE DAMAGE TO THE ROPS CAB OR ROPS CANOPY

MAINTENANCE AND INSPECTION OF THE ROPS CAB OR ROPS CANOPY

ILLUSTRATION OF ROPS CANOPY INSTALLATION4

ILLUSTRATION OF SEAT INSTALLATION

REMOVAL AND INSTALLATION OF ROPS CAB

REMOVAL AND INSTALLATION OF ROPS CANOPY

REMOVAL AND INSTALLATION OF HEATER

REMOVAL AND INSTALLATION OF TEMPERATURE CONTROL

REMOVING THE THREE POINT HITCH

INSTALLING THE THREE POINT HITCH

Cylinder Hydraulic Installation

Three Point Hitch Control Valve and Control Lever Installation

You will find Lot More info in this Manual

ONCE AGAIN THIS IS SCANNED PDF FORMAT ON CD