Environmentally Conscious and Economically Sound Machine Dismantling Forum > Madison, WI

> Welding and Laser Cutting

> Stick Welding

> Rotisserie plans for restoration auto car vehicle truck

Rotisserie plans for restoration auto car vehicle truck

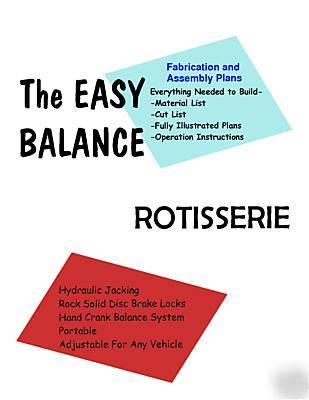

The EASY BALANCE Rotisserie PLANS

Plans can be ordered in standard or metric versions.

These PLANS include 33 pages of construction details for a light, yet sturdy 3,000 lb (1360 kg) capacity rotisserie.

* 3/16" (5mm) Steel Construction: This is the ideal size for strength and compactness, plus it produces a lightweight system for ease of use.

* Built-in Hand Crank Balance System: Balances vehicle perfectly in just a few minutes while the vehicle is mounted on the rotisserie. Allows on-the-fly balance adjustments as components are removed or installed on the vehicle. The adjustment mechanism is sealed and protected from dirt for a long life of continuous, smooth operation.

* Rock-Solid Disc Brake System: Strong, positive locking, automotive brake style mechanism. Securely holds the vehicle in any position with a turn of a bolt. No pins are needed or jam bolts used that can cause metal gouging. THIS DESIGN WILL NOT SLIP!! The vehicle can also be instantly rotated at any time while still holding it in its new position without having to re-adjust the brake.

* Extendable Legs For Additional Stability: With the legs in the full 6 foot extended position, stability is virtually guaranteed when rolling a loaded rotisserie over uneven surfaces. The legs can be equipped with any size caster, solid or pneumatic. The rotisserie can also be built without legs or casters and still be totally stable.

* Easy Storage and Transportation: Both rotisserie ends can be connected together for easy transportation in any standard pick up bed.

* Lightweight But Strong Assembly: This design has a capacity of 3,000 lbs. (1360 kg) and will support the weight of just about any passenger car or light truck with positive stability.

* Hydraulic Jacking System: Allows vehicle to be raised from a 19" bumper height to almost 4 feet off the ground. Floor jacks and jack stands are not needed to mount the vehicle. Just roll the car up to the rotisserie and start jacking.

The construction of this rotisserie only requires basic metal working and welding skills. There are no complicated angles to cut. The most complicated cuts are a few 45 degree angles and a few circles. The rest are square cuts.

The plans use a simple 3D pictorial method of construction without complicated engineering symbols and other terminology to learn. See examples below.

The plans also include a Material List, Parts List, Cut List, Drill Diagram and just one page of Assembly Notes. Operation instructions show how to properly and safely use the rotisserie.

Also available are METRIC versions of the plans. When ordering,

please specify which version you would prefer.

CONTACT ME FOR A FREE SAMPLE OF THE PLANS. YOU CAN SEE HOW EASY IT IS TO FOLLOW THE PLANS AND CONSTRUCT THIS ROTISSERIE.

The pictures below show the typical assembly sequences for the rotisserie's major assemblies.

Before welding begins, all parts are first cut and drilled

according to the Cut List and Drill Diagram,

then assembled according to each page in the plans.

Below is a typical page of the plans.

You can see how Parts "N" and "E" are welded together.

The dotted lines show where each part is located for welding.

Most parts are centered with each other.

Notes are included if they need to be welded in other locations.

The next page shows how to weld the previously assembled parts "E" and "N" to Part "D".

Note that "E" and "N" is welded 3-1/2"

from the bottom of part "D" in this case.

Here's where it all comes together.

The Base Assembly is now complete

The rest of the rotisserie is built in same, simple way