Environmentally Conscious and Economically Sound Machine Dismantling Forum > Kenosha

> Welding and Laser Cutting

> TIG Welding of Steel

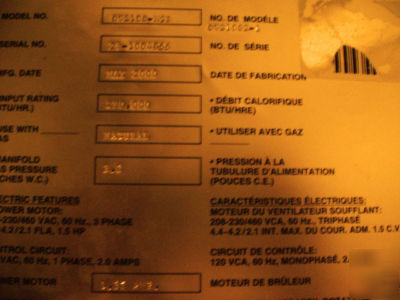

> Baxter OV210G-M2B rack oven

Baxter OV210G-M2B rack oven

This oven is fully functional and has 2 aluminum racks, a stainless steel ramp assembly, 4 hood filter panels that are included with this item.

GAS FIRED ADVANTAGE 2B UTILITIES:

GAS CONNECT POINT: 1-1/4" Pipe Size.

Oven control: 6 amps (Clean

Blower motor 1-1/2 HP (3ph)

4.4-4.2 amps (3ph) or 7 amps

WATER CONNECT POINT: 1/2" pipe

size. Cold water @ 45 psi. (310 kPa)

minimum @ 3.0 G.P.M. (.19 liters/sec)

HOOD VENT: 8" (20.3 cm) diameter connection collar.

[0.4" w.c. (100Pa) static pressure drop through hood.]

DRAIN FITTING: Choose either rear or font drain and plug the drain connection that is not in use. route to air-gap drain.

M2243-4: Prison Safety Package

To reduce the risk of fire, the appliance is to be mounted on floors of non-combustible construction with non-combustible flooring and surface finish and with no combustible material against the underside thereof, or on non-combustible slabs or arches having no combustible material against the underside thereof. Such construction shall in all cases extend no less than 12 inches beyond the equipment on all sides.

IMPORTANT: Do not route any utilities (wiring, plumbing etc) in or under the non-combustible floor under the oven.

MINIMUM CLEARANCES TO COMBUSTIBLE CONSTRUCTION:

ZERO INCHES FROM SIDES AND BACK. TEN FEET MINIMUM CEILING HEIGHT.

(For tilt-up and utilities access)

NOT APPROVED FOR INSTALLATION ON COMBUSTIBLE FLOOR SURFACES.

The oven is of unitized construction with pre-packed panels. Exterior surfaces shall be of 300 series stainless. Interior baking chamber shall be of 300 series stainless. The ventilation hood shall be of 300 series stainless, comply with NFPA 96 requirements and be an integral part of the oven. A flat 300 series stainless floor shall be used to facilitate loading and unloading (ramps are not required).

The control panel shall have full auto-program ability - up to 84 programs. The panel shall consist of the following digital components: Thermostat, steam timer, bake timer and blower delay circuit.

The thermostat shall have F and C ability. The actual bake temperature and set temperature shall be digitally displayed. A steam damper shall be an integral part of the construction. Pulse air flow shall be a standard air management control.

The oven shall be pre-wired and pre-fired at the factor. The heat exchanger core shall be of up-flow serpentine design. The turbine rotor shall be dynamically balanced with the 1 1/2 HP motor. Hood is fully welded with grease trough, drain cup and UL classified grease filters. Ventilator fan will be required. Products of combustion and camber vents are factory ducted to the integral hood. An oven powered connection point (120V, 10A, 1/3 HP) is provided for automatic operation of your roof-top hood ventilator fan. Airflow proving switch is factory installed.

The oven shall be equipped with a steam generator of mild steel positioned directly in the suction air flow. The water inlet shall be controlled by the steam timer, solenoid valve, strainer and flow rate control with gauge. The bake chamber shall be illuminated by an incandescent light external to the bake chamber and accessible from the oven front.

The oven door shall be fully insulated and have a full length view window minimum of 56"L. The door and jamb arrangement shall accommodate both right and left hand hinges (changeable on site)

An automatic heavy duty lift system shall be a standard feature using one piece lifting framework and supported by the structural frame of the oven. The baking rack shall be removed from either end of the lifting device.

Self lubricating high temperature bearings and self adjusting rotor clutch are standard features. The carrier will have the ability to hold 1 single rack (side or end load)

Site requirements and electrical/ mechanical specifications are as above.

Purchaser is responsible for all installation costs and for providing:

Labor to unload oven upon arrival. Installation mechanics. All local service connections including: electricity, vents, gas, water and drain per local code.

A FACTORY TECHNICIAN OR FACTORY AUTHORIZED INSTALLATION TECHNICIAN MUST SUPERVISE AND APPROVE ANY INSTALLATION.