Environmentally Conscious and Economically Sound Machine Dismantling Forum > Kenosha

> Welding and Laser Cutting

> TIG Welding of Steel

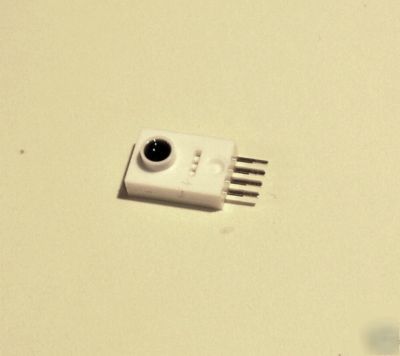

> New pressure sensor, silicon transducer, 0-300MM hg rel

New pressure sensor, silicon transducer, 0-300MM hg rel

Motorola Part MPX2301DT1 (now Freescale Semiconductor)

You connect a hose to the sensor's inlet port, and it measures the pressure in the tube. A hermetic gel protects the semiconductor wafer from contaminants in the medium to be measured.

Hookup is, (from left): VCC, Out+, Out-, GND.

You can find application info on the web.

All pressure sensors are essentially a Wheatstone Bridge on a silicon wafer, see below

http:// /HowPage004.html

You apply a DC voltage at the top and bottom of the bridge, and you measure the differential voltage at the remaining 2 middle terminals. Best done by feeding these to the +/- inputs of an opamp or instrumentation (differential) amp.

A typical application (for a different sensor, pinout has different order, but same connections)

http:// /pic/files/altim1c.gif

If you look at all application schematics ( many are for altimeters, by hobbyists) you see a common denominator: 2 pins to supply, 2 pins to an op-amp's differential inputs.

NB. Avoid using any schematic that mentions the Motorola MPX4xxx or 5xxx series, as these are Absolute pressure sensors, and have different pin assignments, different implementation.

NOTE: The silicon die and gold wire bonds are exposed on the back of the device. Application mounting must ensure mechanical protection from this side. Simply mounting the part flat on a PCB, as in the top photo will provide that protection.