Environmentally Conscious and Economically Sound Machine Dismantling Forum > Milwaukee

> Antiques

> Cast Iron Machines

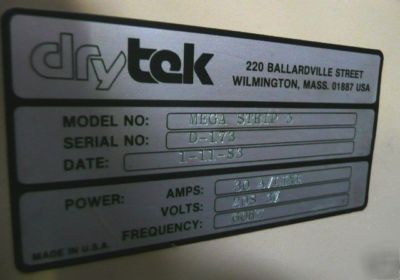

> Drytek mega strip 5

Drytek mega strip 5

Removes the photoresist from an etched wafer. Using a plasma source, a monatomic reactive species is generated. The reactive species combines with the photoresist to form ashing which is removed with a vacuum pump.

Photoresist Stripping, ashing is used as a dry process method for the removal of organic polymers (negative, positive, or electron beam photoresists.) The Drytek Mega Strip utilizes a passivation method which produces active species at the wafer.

A catalyst gas can be mixed with oxygen to produce rapid and efficient photoresist removal, e.g.: CF4 or SF6 over aluminum or silicon dioxide films. Since photoresist removal is an exothermic reaction, increased temperature will increase the etch rate; a heater is located on the substrate electrode maintaining a constant temperature while in standby. The Drytek Mega Strip utilizes a capacitance manometer to measure the pressure and signal the controller to adjust the throttle valve located in the main pumping line.

The chamber has separate compartments to optimize removal of the photoresist.

Not tested but looks to be in excellent condition.