Environmentally Conscious and Economically Sound Machine Dismantling Forum > Milwaukee

> Antiques

> Leather FLat Belt Eqiuptment

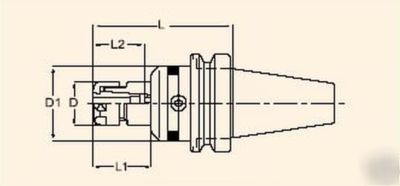

> Nikken bt 30 bulls-eye SK16 slim chuck

Nikken bt 30 bulls-eye SK16 slim chuck

Nikken BT 30 Bulls-Eye SK16 Slim Chuck

The Bull's-Eye Chuck can be easily adjusted to reduce the run-out of the cutting tool to zero at the tip in less than a minute. The adjustability of Lyndex-Nikken's Bull's-Eye Chuck produces longer tool life, improved part accuracy, and better surface finish. After a machine tool has been used for 2-3 years, the run-out accuracy of the spindle will decline by 0.01mm - 0.04mm at 100mm from the gauge line. The Bull's-Eye Chuck allows for the correction of this error, and reduces run-out to 0.001 - 0.002mm.

When the run-out accuracy of 21 microns is reduced to 3 microns, the tool life can be improved by approximately 5 times.

1. Loosen the two Cam Ring Lock Screws and rotate the Cam Screw to the free position. Set the dial Gage to the front end of the cutting tool.

2. Rotate the tool to establish the position of maximum run-out. Turn the Cam Ring and locate the Cam Screw at the maximum run-out position.

3. Using the supplied hex wrench, turn the Cam Screw until the run-out decreases to the medium value between maximum and minimum.

4. To confirm: rotate the toolholder to check the run-out. If the run-out is not satisfactory, return the Cam Screw to the free position and repeat from Step 2. Finally, tighten the two Ring Lock Screws.